Welding Cable Sizes Chart

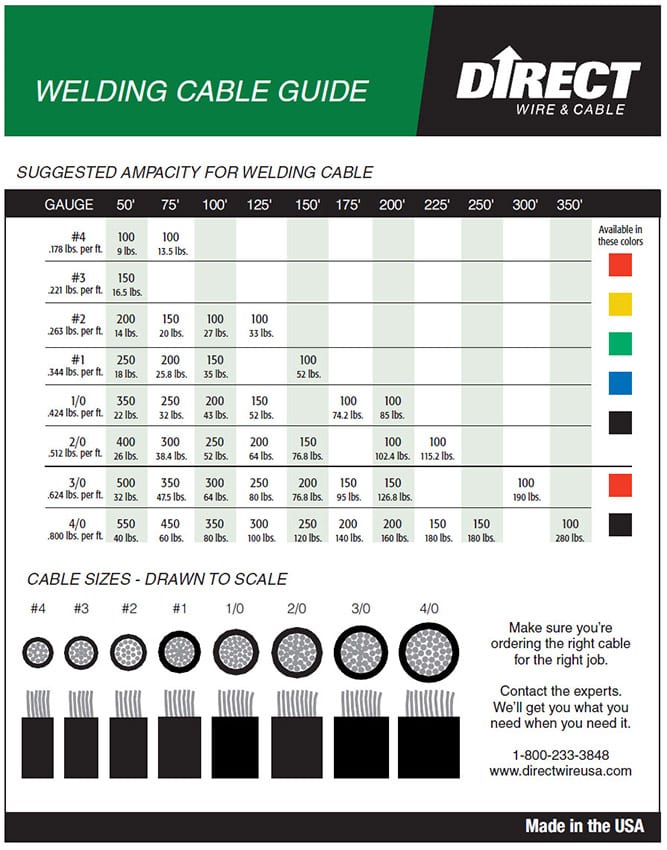

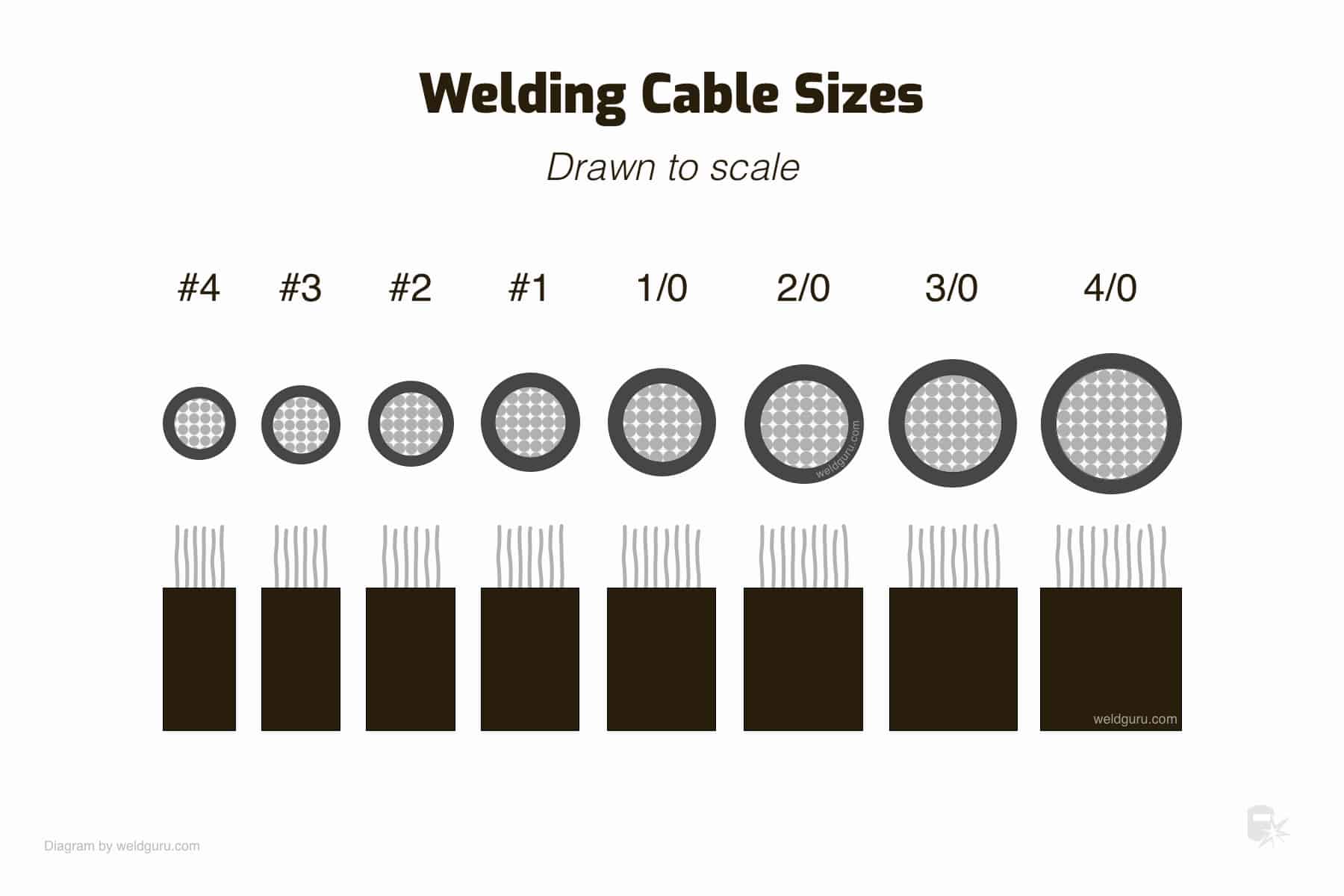

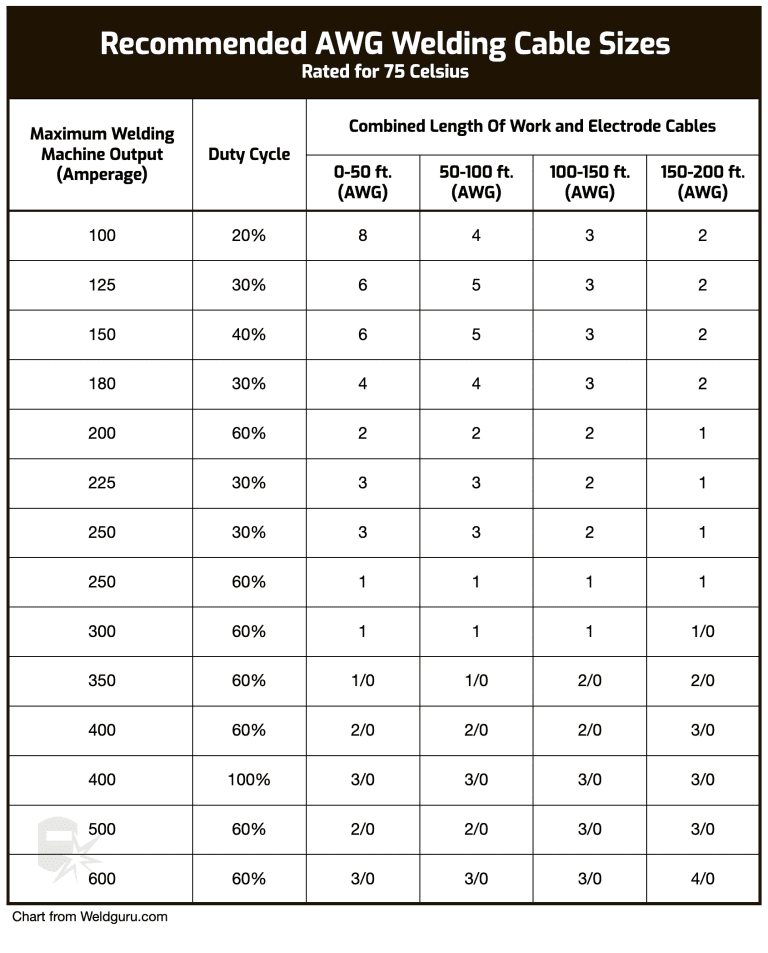

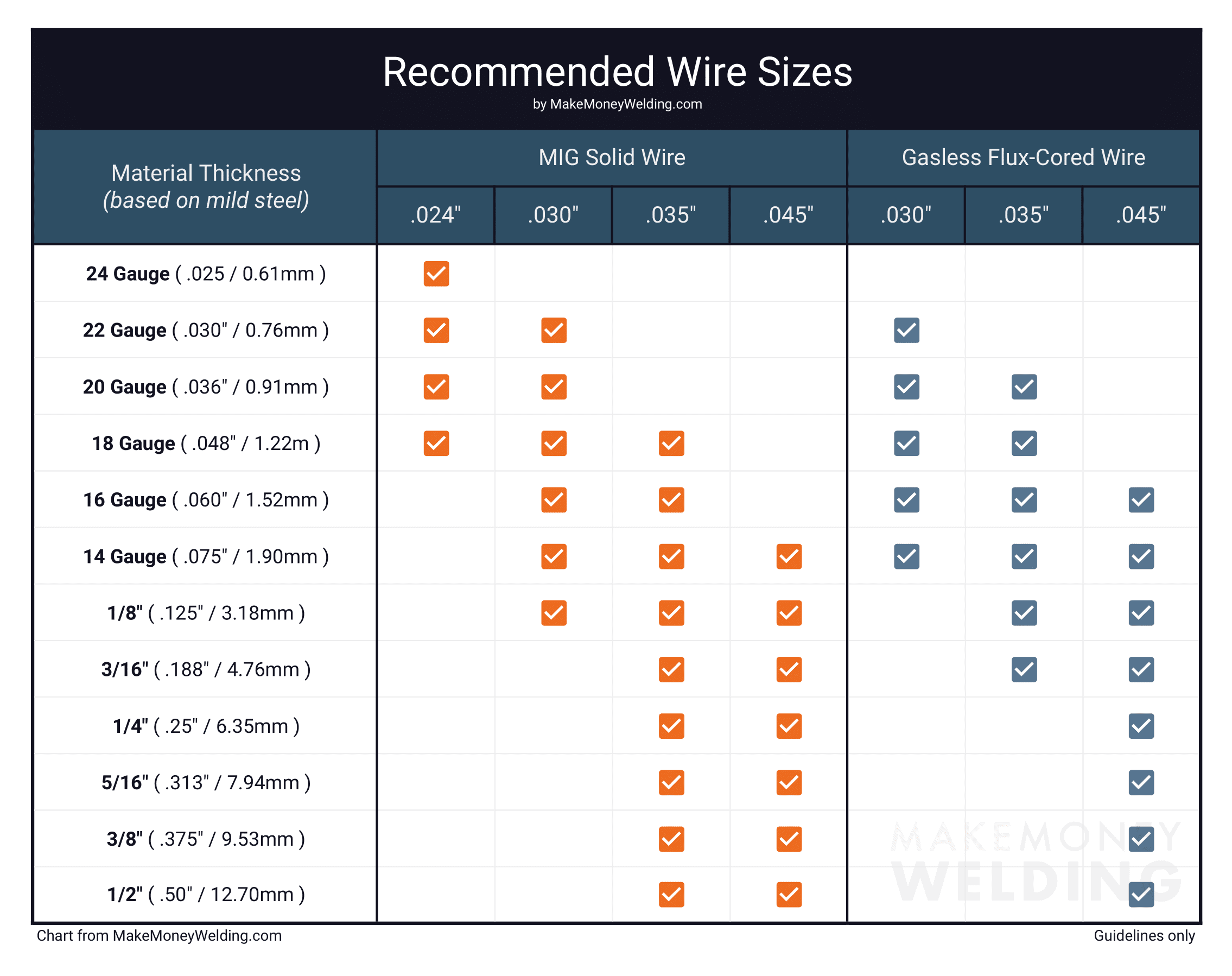

Welding Cable Sizes Chart - Selecting the appropriate mig wire size is crucial for successful welding. American wire gauge (awg) metric cable sizes. If you're looking for welding service provider in orlando, fl, make sure to hire the professionals from s & g mobile welding. Web a welding cable chart contains some information you need to know about the right cable size. This proactive approach minimizes voltage drop, ensures stable arc characteristics, and enhances overall welding quality. Web consulting the welding cable size chart enables welders to match cable size with the anticipated welding current. Copper core vs aluminum core welding cable. How do we measure the welding cable sizes? The core of a welding cable basically contains hundreds of layers of electrical conductors such as copper or aluminum. The electrode cable attaches to either an electrode holder, tig torch or wire feeder. View the awg reference table below for dimensions and sizing. Utilize a cable size chart. Web the minimum number of branch circuits shall be determined from the total calculated load and the size or rating of the circuits used. Find your amperage output on the list to check what kind of cable you need. How do we measure the welding cable sizes? American wire gauge (awg) metric cable sizes. Web with a cable sizing chart, you can find the appropriate wire gauge for your situation. Other steel fabricated products include flotation pontoons for dredging operations, large diameter welded pipe, duct work, bins and hoppers. Web for challenging storage applications, rubber or baked phenolic linings are available via subcontract. Web february 26, 2024november 28, 2023 by sohagarbin. Copper core vs aluminum core welding cable. View the awg reference table below for dimensions and sizing. Selecting the appropriate mig wire size is crucial for successful welding. The core of a welding cable basically contains hundreds of layers of electrical conductors such as copper or aluminum. The electrode cable attaches to either an electrode holder, tig torch or wire. In all installations, the number of circuits shall be sufficient to supply the load served. Figure 2 shows a comparison between welding cables in awg sizes and metric sizes. Web a welding cable chart contains some information you need to know about the right cable size. American wire gauge (awg) metric cable sizes. This proactive approach minimizes voltage drop, ensures. These charts simplify the process, but there are more complex calculations that need to be followed. Figure 2 shows a comparison between welding cables in awg sizes and metric sizes. Web choosing the right size welding cables is important because you don’t want your machine to work improperly or catch fire. View the awg reference table below for dimensions and. Luckily, a standardized size chart using american wire gauge sizing tells you which size to. The electrode cable attaches to either an electrode holder, tig torch or wire feeder. In all installations, the number of circuits shall be sufficient to supply the load served. Web for challenging storage applications, rubber or baked phenolic linings are available via subcontract. Web february. American wire gauge (awg) metric cable sizes. A mig wire size chart provides recommended wire diameters for different metal thicknesses. Figure 2 shows a comparison between welding cables in awg sizes and metric sizes. Web wrong sizes can lead to power loss, overheating, and damage to the equipment and environment. Welding cable size is measured by the american wire gauge. The work cable attaches to a work clamp. Risks of incorrect cable size. Web for determining proper welding cable size, you need to add together the full lengths of the electrode cable and the work cable. Web with a cable sizing chart, you can find the appropriate wire gauge for your situation. The electrode cable attaches to either an electrode. Measure your welding circuit length. The electrode cable attaches to either an electrode holder, tig torch or wire feeder. View the awg reference table below for dimensions and sizing. Web wrong sizes can lead to power loss, overheating, and damage to the equipment and environment. Web in this article, we’ll navigate the key points, from deciphering cable and lead size. This proactive approach minimizes voltage drop, ensures stable arc characteristics, and enhances overall welding quality. Risks of incorrect cable size. The work cable attaches to a work clamp. Web here is the best way to use reference charts for ordering the correct sizes of welding cable for the shop, along with some basic guidelines to follow. Web wrong sizes can. Understand your power source output. Web the welding wire size chart is a crucial guide for selecting the right welding wire size, which varies according to material thickness and type of welding. Standard sizes range from 0.023 to 0.045 inches for welding various metal gauges. It is important to pick an ideal welding cable size that meets the welding needs.. Web the minimum number of branch circuits shall be determined from the total calculated load and the size or rating of the circuits used. Web for challenging storage applications, rubber or baked phenolic linings are available via subcontract. The core of a welding cable basically contains hundreds of layers of electrical conductors such as copper or aluminum. Web for determining. Web for challenging storage applications, rubber or baked phenolic linings are available via subcontract. Web a welding cable chart contains some information you need to know about the right cable size. To help you make a wise decision, here’s a table showing the recommended welding cable size for different amperage ratings. Web with a cable sizing chart, you can find the appropriate wire gauge for your situation. Find your amperage output on the list to check what kind of cable you need. Other steel fabricated products include flotation pontoons for dredging operations, large diameter welded pipe, duct work, bins and hoppers. Web consulting the welding cable size chart enables welders to match cable size with the anticipated welding current. Standard sizes range from 0.023 to 0.045 inches for welding various metal gauges. Understand your power source output. Web this document provides guidance on the safe and proper selection of welding cables. This includes identifying specific criteria including minimum copper content, gauge sizing, electrical performance, and resistance for welding cable sizes. The core of a welding cable basically contains hundreds of layers of electrical conductors such as copper or aluminum. How do we measure the welding cable sizes? Web the minimum number of branch circuits shall be determined from the total calculated load and the size or rating of the circuits used. Web choosing the right size welding cables is important because you don’t want your machine to work improperly or catch fire. View the awg reference table below for dimensions and sizing.welding cable size chart pdf Wiring Diagram and Schematics

WeldingCableSizeAmperageChart Toll Gas & Welding Supply

Welding Cable Ampacity Chart

Welding Cable Size Guide Charts & Tips for the Right Choice

Welding Cable Wire Size Chart Welding Mania

Welding Cable Size Chart

Welding Cable Size What's Best? (with Chart)

Welding Cable Size Chart

MIG Welding Wire Essentials A Guide to Types & Uses

Welding Cable Size What’s Best? (with Chart)

Web In This Article, We’ll Navigate The Key Points, From Deciphering Cable And Lead Size Charts To Pinpointing The Exact Cable Size That Fits Your Specific Needs Using Guidance From Aws F4.2:2020 Handbook.

Selecting The Appropriate Mig Wire Size Is Crucial For Successful Welding.

A Mig Wire Size Chart Provides Recommended Wire Diameters For Different Metal Thicknesses.

Web The Welding Wire Size Chart Is A Crucial Guide For Selecting The Right Welding Wire Size, Which Varies According To Material Thickness And Type Of Welding.

Related Post: