Size Of Welding Rod Chart

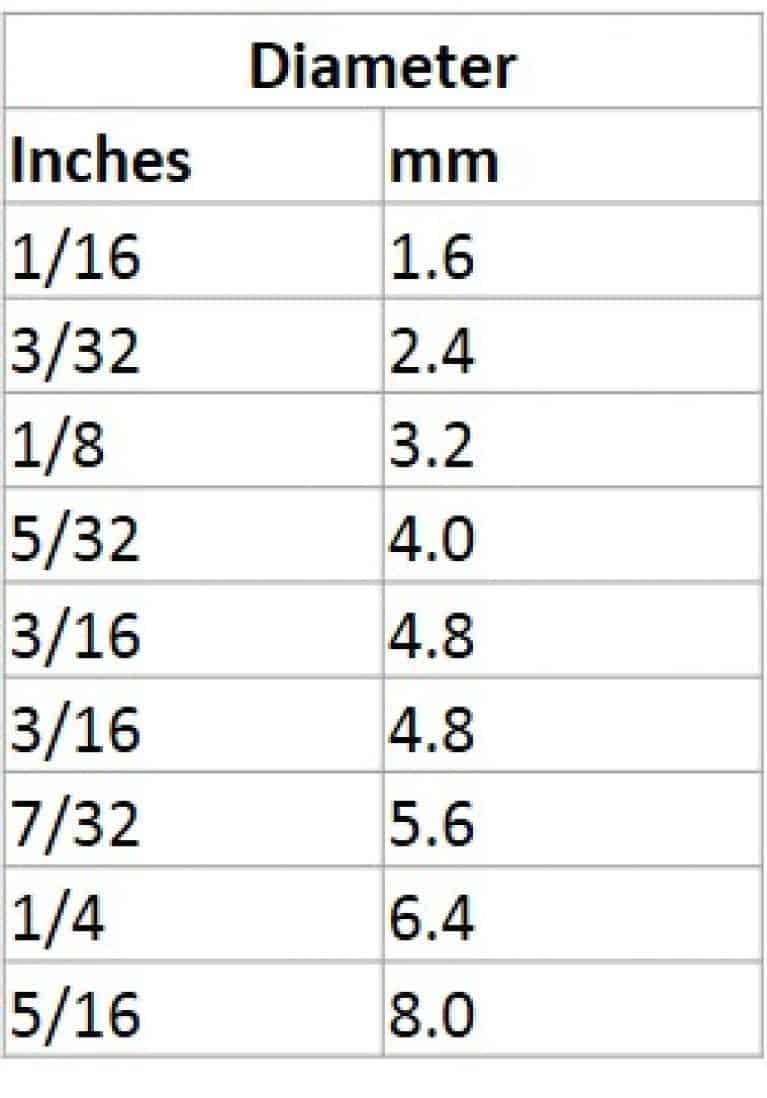

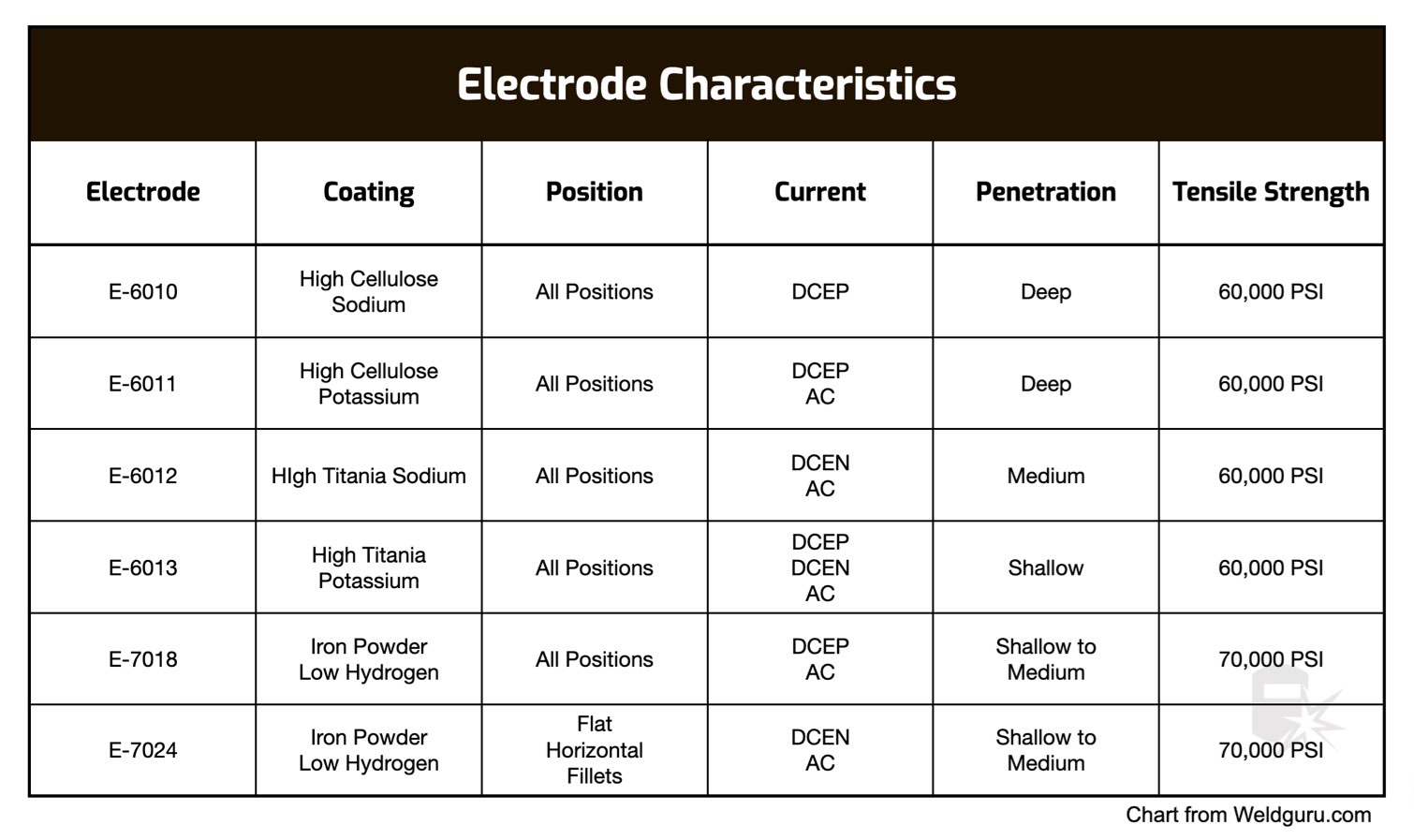

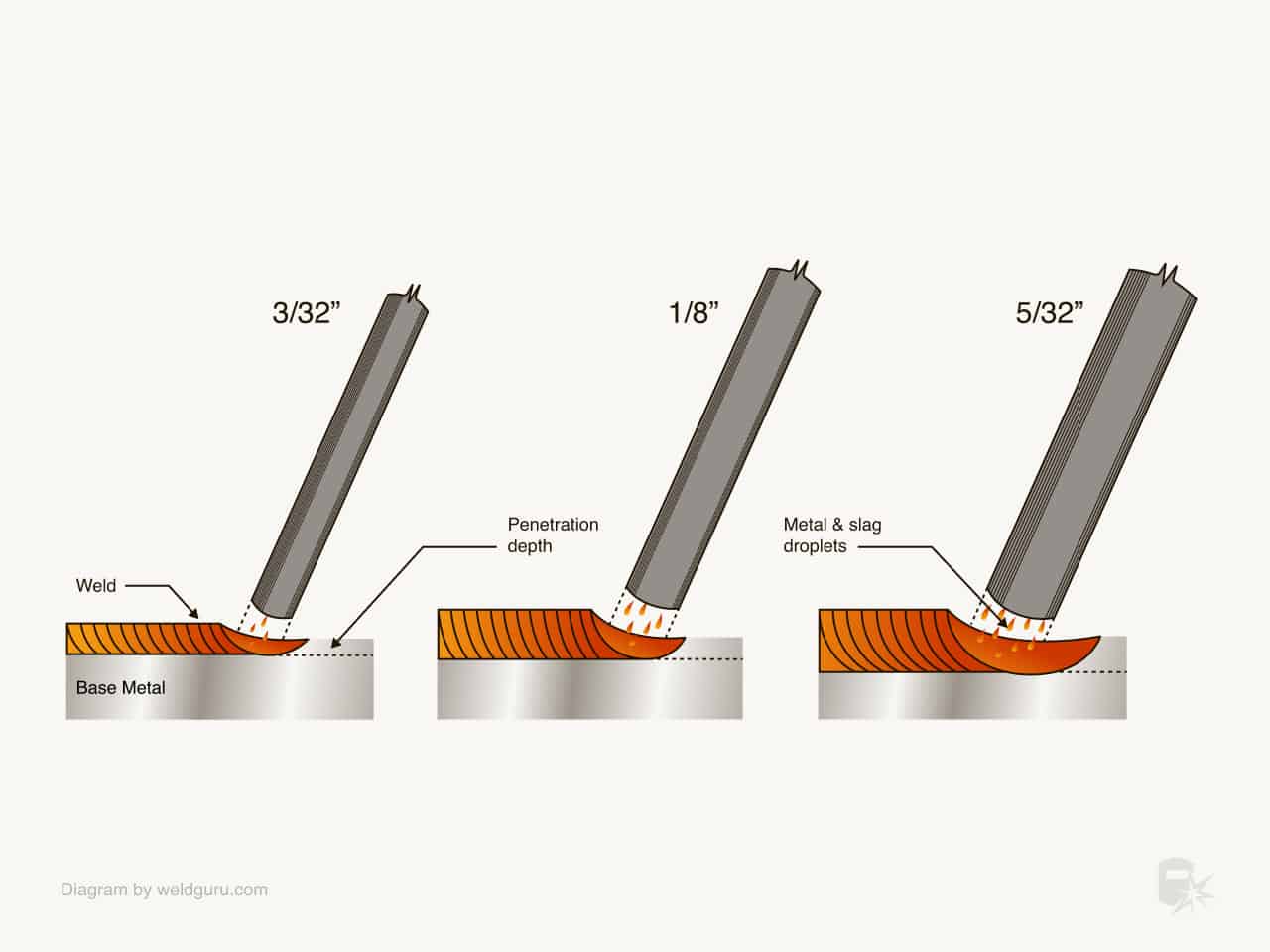

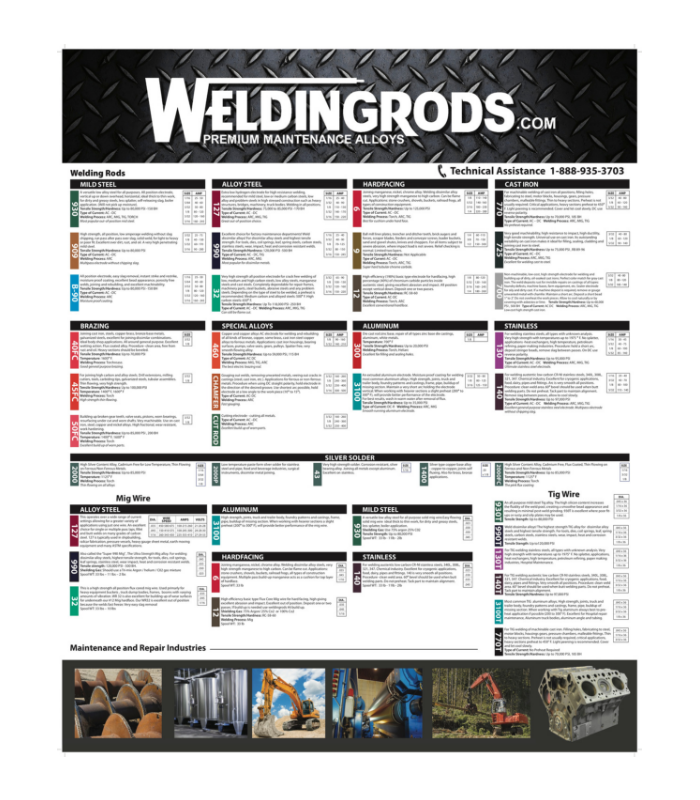

Size Of Welding Rod Chart - The numbers in the classification refer to the properties of the electrode and how it can be used for the best performance. Take a look at the image below to see a typical stick welding setup. This chart provides valuable information on which rod size to use for different metal thicknesses and welding positions. Web aws classification numbers explained. What are the common sizes of tig welding rods? The stick welding process is also called shielded metal arc welding (smaw). 2.1 how is welding rod diameter measured? Web this page serves as a point of reference and a guide for selecting the right stick welding rod size and amperage to get the best results when stick welding. 3.1 thickness of the metal and electrode size. Web to choose the right welding rod, you need to: How to build welding lead reels. Web to help you identify the appropriate stick welding rod for your projects, refer to the stick welding rod size chart below. What is the best welding rod for a beginner?. Web this chart should serve as a guide for all your welding rod size needs and will provide education and knowledge about the selection process as well. This size is used for carbon steel. The table is published in aws a5.1 specification. Web stick (smaw) welding rods are available in a variety of diameters, ranging from 3/32 inch up to 1/4 inch. You can use below welding rod sizes chart to choose the welding amperage for different diameters of welding rods used for carbon steel welding. Take a look at the image below to see a typical stick welding setup. Anything up to 1/4″ (6.35 mm) thick would be best welded with a 1/8″ (3.2 mm) electrode, and thicker metal would use 5/32″ (4.0 mm). 2.1 how is welding rod diameter measured? Take a look at the image below to see a typical stick welding setup. 3.2 how welding positions affect electrode size choice. Web if you are a beginner in the welding industry, you may be confused upon looking at the welding rod classification, for you would readily notice that the welding rod chart. Web how to select stick welding rod type, size, and amperage. Take a look at the image below to see a typical stick welding setup. Know about the tensile strength of metals. Below is a chart that will give you a starting point for choosing the correct welding rod size. The most common diameter for general purpose welding is 3/32,. What is the best welding rod for a beginner?. Below is a chart that will give you a starting point for choosing the correct welding rod size. In this article, i’ll cover the most common welding rod sizes to help you pick the most suitable one for your needs. Web the most popular welding rod sizes for home welders are. Web for material smaller than 1/8″ (3.2 mm), a 3/32″ (2.4 mm) rod will be a good choice. Now, let’s break down some different size types for jobs with different metals: 3.2 how welding positions affect electrode size choice. Web welding rod sizes explained. 2.1 how is welding rod diameter measured? There are a variety of factors that go into choosing the right electrode for each project. What are the common sizes of tig welding rods? Web to help you identify the appropriate stick welding rod for your projects, refer to the stick welding rod size chart below. Proper rod storage to retain performance. Web if you are a beginner in. What is the best welding rod for a beginner?. 2.1 how is welding rod diameter measured? Know about the tensile strength of metals. Web to choose the right welding rod, you need to: Web see the chart below that details some of the weld characteristics for each coating. How to choose a correct welding rod size. An electrode is a metal wire that is coated. Web see our chart and guide on how to select the right welding rod size diameter and amperage depending on metal thickness and other variables. This size is used for carbon steel. You should not be perplexed with these numbers for these numbers. Web how to select stick welding rod type, size, and amperage. Web for material smaller than 1/8″ (3.2 mm), a 3/32″ (2.4 mm) rod will be a good choice. The numbers in the classification refer to the properties of the electrode and how it can be used for the best performance. 3.2 how welding positions affect electrode size choice. We. What size welding rod for general purpose? How do you know what size welding rods to use? Web neglecting position and joint type. The american welding society (aws) has created a numbering classification 5.1 that is the most commonly used way of differentiating between stick electrodes. This chart provides an overview of the most common stick welding rod sizes and. We cover everything related to rod types, sizes, and how to pick the right one for your needs. Web for material smaller than 1/8″ (3.2 mm), a 3/32″ (2.4 mm) rod will be a good choice. Web aws classification numbers explained. Now, let’s break down some different size types for jobs with different metals: Welding electrodes are consumable welding sticks. There are a variety of factors that go into choosing the right electrode for each project. Web welding electrodes & filler rods explained. Welding electrodes are consumable welding sticks used for welding projects and machines to weld together metals in the stick welding process. What size welding rod for general purpose? Take a look at the image below to see a typical stick welding setup. Whether you’re a beginner or an established welder, you need to acquaint yourself with knowledge of welding rod sizes. We cover everything related to rod types, sizes, and how to pick the right one for your needs. Plus a chart with rod size and amperage per metal thickness in inches and mm. Web the most popular welding rod sizes for home welders are 3/32″, 1/8″, and 5/32″, as they are suitable for common projects. 3.2 how welding positions affect electrode size choice. Consider the base metal (s) you will be welding. Web to choose the right welding rod, you need to: Balancing quality and economic factors. Different welding rods sizes, types, and their uses. Anything up to 1/4″ (6.35 mm) thick would be best welded with a 1/8″ (3.2 mm) electrode, and thicker metal would use 5/32″ (4.0 mm). Web see the chart below that details some of the weld characteristics for each coating.Welding Rods for Stick Welding The Definitive Electrode Guide (2019)

Stainless Steel Welding Rod Chart

Aluminum Welding Rod Chart SexiezPix Web Porn

Aluminum Filler Rod Selection Chart

Mig Welding Settings Chart Metric Pdf

Welding

Size Of Welding Rod Chart

Thickness Welding Rod Sizes Chart

Welding Rod Sizes How To Choose the Right Electrode Weld Guru

Welding Rod Chart

Know About The Tensile Strength Of Metals.

Know About Current And Polarity.

Plus You'll Get The Most Complete Welding Rod Chart On The Internet In Pdf!

The American Welding Society (Aws) Has Created A Numbering Classification 5.1 That Is The Most Commonly Used Way Of Differentiating Between Stick Electrodes.

Related Post: