Six Sigma Control Chart

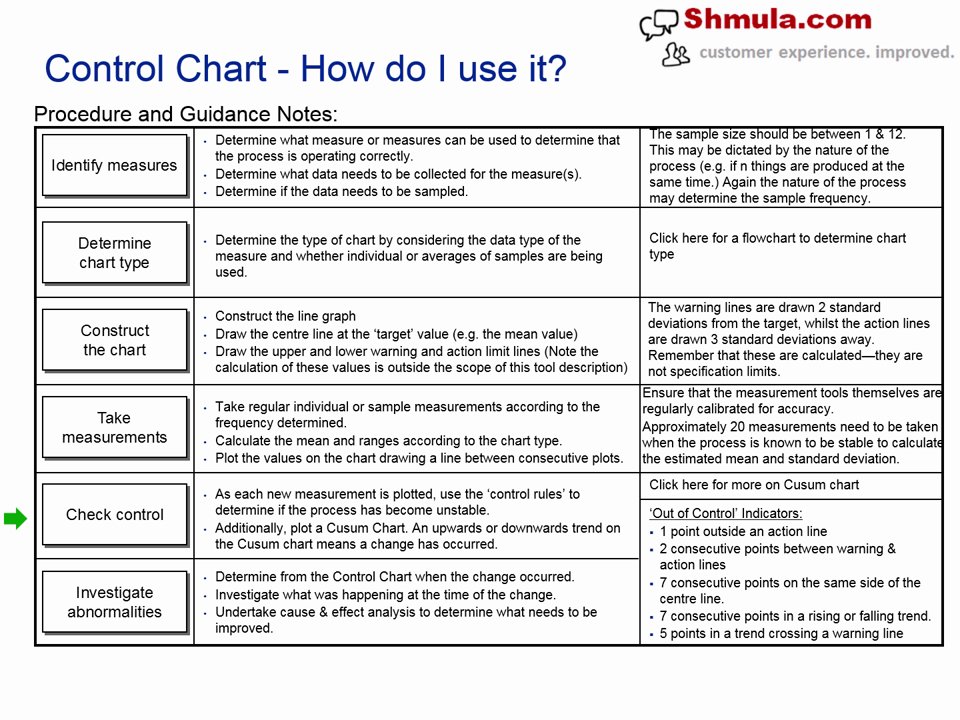

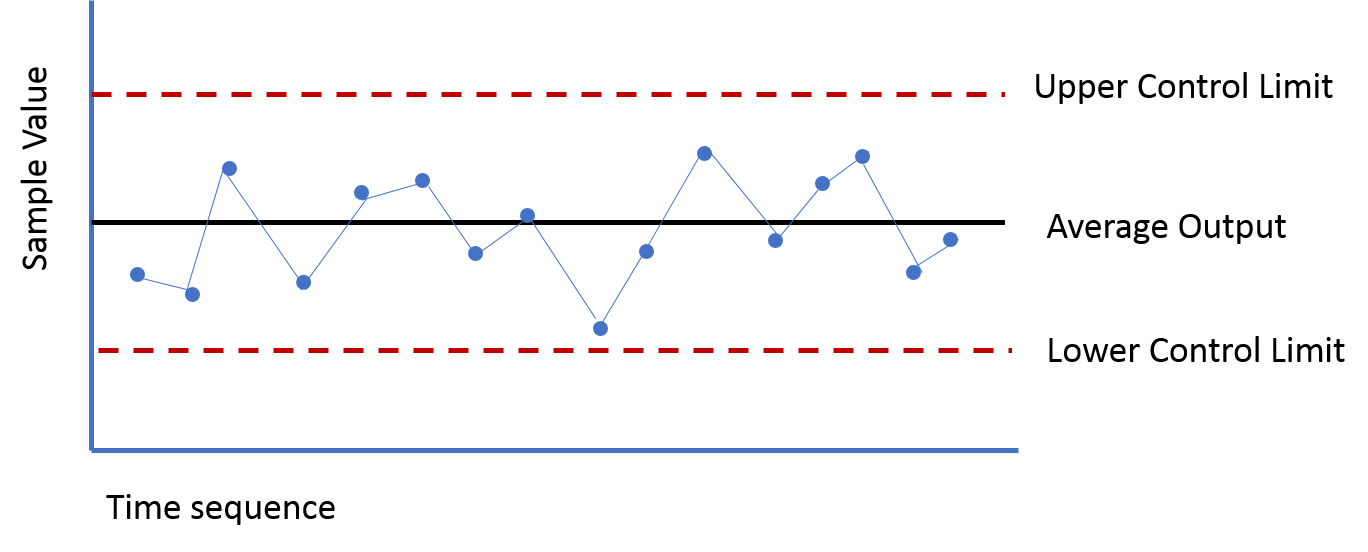

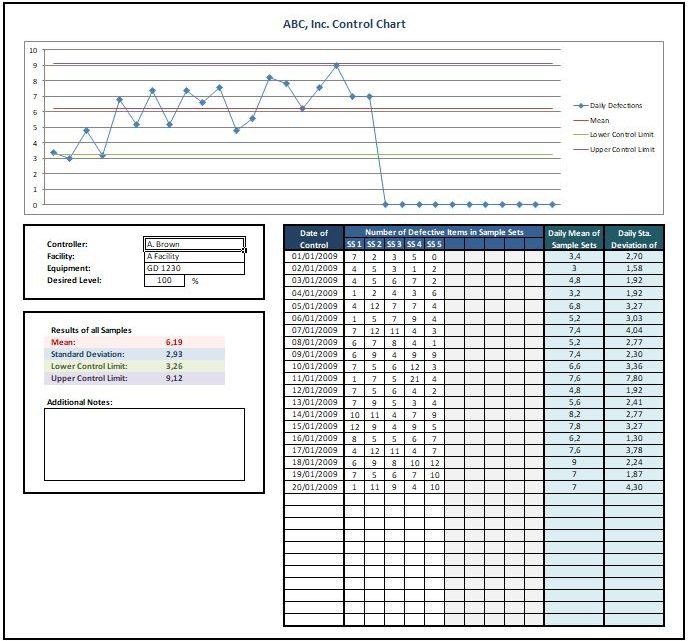

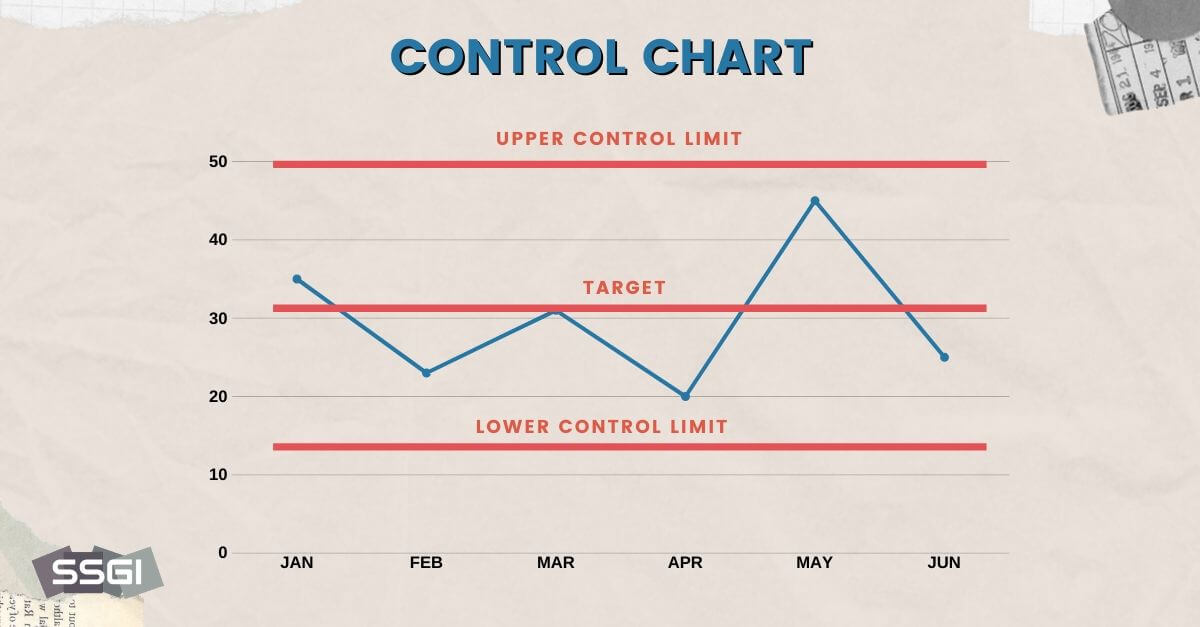

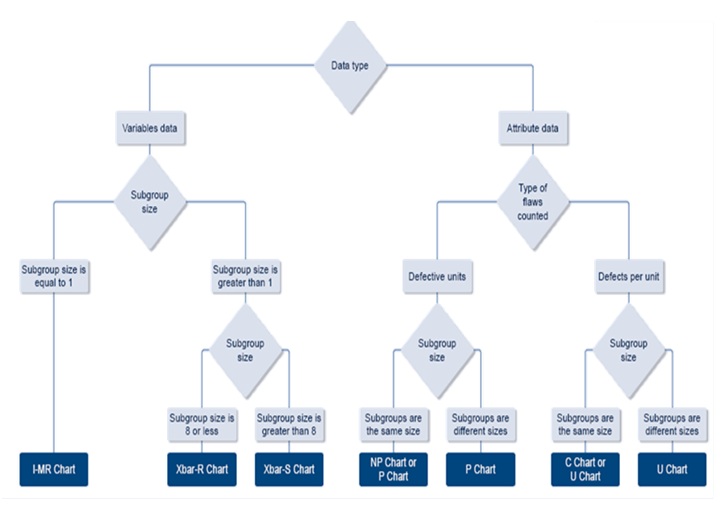

Six Sigma Control Chart - Read this chapter, which gives a clear description of six sigma, when it is used, and how to interpret the results. Control charts are commonly used in six sigma projects to monitor and control processes, ensuring that they meet customer requirements and perform within acceptable limits. Business enterprises can identify and address process deviations by plotting data points against control limits leading to improved quality, reduced defects, and enhanced overall performance. Web related term or concept 2: The charts help us track process statistics over time and help us understand the causes of the variation. Web x bar r charts are the widely used control charts for variable data to examine the process stability in many industries (like hospital patients’ blood pressure over time, customer call handle times, length of a part in a production process, etc). Web the control chart is a graphical display of quality characteristics that have been measured or computed from a sample versus the sample number or time. Web some of the more common control charts are the xbar and r chart, imr chart, p and np charts, and c and u charts. Web every process falls into one of four states: Web control charts play a crucial role in the six sigma methodology by enabling statistical process control (spc). Not predictable and produces defects at an unacceptable rate. Web control charts are time charts designed to display signals or warnings of special cause variation. Web control charts are used as a way to display the performance of a process over time. Web six sigma control charts are significant in monitoring and controlling process variation within the six sigma methodology. Read this chapter, which gives a clear description of six sigma, when it is used, and how to interpret the results. Introduced by walter shewhart’s pioneering work and then enhanced through w. In six sigma studies, we read control charts in the control phase, like the statistical process cont control chart (spc chart). Web related term or concept 2: By this, we can see how is the process behaving over the period of time. Control charts are commonly used in six sigma projects to monitor and control processes, ensuring that they meet customer requirements and perform within acceptable limits. Web an ultimate guide to control charts in six sigma. Web the main focus of control charts is to detect and monitor the process variation. Web the six sigma method lets organizations identify problems, validate assumptions, brainstorm solutions, and plan for implementation to avoid unintended consequences. Celebrate success and recognize the team. Special cause variation, as distinct from common cause. Introduced by walter shewhart’s pioneering work and then enhanced through w. When one is identified, mark it on the chart and investigate the cause. By this, we can see how is the process behaving over the period of time. Web the control chart is a graphical display of quality characteristics that have been measured or computed from a sample versus. Produces 100 percent conformance and is predictable. Web a six sigma control chart is a simple yet powerful tool for evaluating the stability of a process or operation over time. Know how to use a control chart along with the advantages of implementing six sigma chart. Web an ultimate guide to control charts in six sigma. Not predictable and does. Web x bar r charts are the widely used control charts for variable data to examine the process stability in many industries (like hospital patients’ blood pressure over time, customer call handle times, length of a part in a production process, etc). Not predictable and does not produce defects. They are used extensively during the measure and analyze phases of. Determine the appropriate time period for collecting and plotting data. Web some of the more common control charts are the xbar and r chart, imr chart, p and np charts, and c and u charts. Introduced by walter shewhart’s pioneering work and then enhanced through w. The control phase is approximately a 2 to 3 weeks process. Creating a control. By this, we can see how is the process behaving over the period of time. Web control charts are used in the control phase of the dmaic (define, measure, analyze, improve, and control) process. Web six sigma control charts are significant in monitoring and controlling process variation within the six sigma methodology. Web you can use control charts to determine. The activities in the control phase are to create and update standard works or work instructions. They monitor and analyse process variations. Data for the control chart can be selected randomly or over a specified time period. Web you can use control charts to determine if your process is under statistical control, the level of variation native to your process,. They are used extensively during the measure and analyze phases of the dmaic approach to understand process capabilities and identify sources of variation. The charts help us track process statistics over time and help us understand the causes of the variation. This allows us to see how the process behaves over time. Let’s get started on the journey to discover. Not predictable and does not produce defects. The control phase is approximately a 2 to 3 weeks process. Web the descriptions below provide an overview of the different types of control charts to help practitioners identify the best chart for any monitoring situation, followed by a description of the method for using control charts for analysis. This allows us to. Not predictable and does not produce defects. Control charts are commonly used in six sigma projects to monitor and control processes, ensuring that they meet customer requirements and perform within acceptable limits. This allows us to see how the process behaves over time. Web six sigma control charts are significant in monitoring and controlling process variation within the six sigma. Control charts are the basis of statistical process controls methodologies, and are used to distinguish between random/uncontrollable variations and controlled/correctable variations in a system. Determine the appropriate time period for collecting and plotting data. Web control charts play a crucial role in the six sigma methodology by enabling statistical process control (spc). Web you can use control charts to determine if your process is under statistical control, the level of variation native to your process, and the nature of the variation (common cause or special cause). Web the main focus of control charts is to detect and monitor the process variation. In the control chart, these tracked measurements are visually compared to decision limits calculated from probabilities of the actual process performance. Control charts are commonly used in six sigma projects to monitor and control processes, ensuring that they meet customer requirements and perform within acceptable limits. Web the descriptions below provide an overview of the different types of control charts to help practitioners identify the best chart for any monitoring situation, followed by a description of the method for using control charts for analysis. Web the six sigma method lets organizations identify problems, validate assumptions, brainstorm solutions, and plan for implementation to avoid unintended consequences. The activities in the control phase are to create and update standard works or work instructions. Celebrate success and recognize the team. Web six sigma control charts are essential tools within the six sigma methodology. Collect data, construct your chart and analyze the data. Web control charts are used as a way to display the performance of a process over time. A control chart is also known as the shewhart chart since it was introduced by walter a shewhart. When one is identified, mark it on the chart and investigate the cause.Control Chart Rules Six Sigma A Visual Reference of Charts Chart Master

Control Charts Six Sigma

What is Control Charts in Six Sigma and How to Create them?

Six Sigma Control Charts

Control Chart 6 sigma Spreadsheet

6 Sigma Control Chart Introduction Toolkit from Leanscape

Lean Six Sigma The Definitive Guide (2024) SSGI

Full Guide To Six Sigma Control Charts

6 Sigma Control Chart Introduction Toolkit from Leanscape

Six Sigma DMAIC Process Control Phase Control Chart Selection

They Monitor And Analyse Process Variations.

Creating A Control Chart Requires A Graph That Covers A Period Of Time, A Center Line That Shows The Results Of A Process During That Time, And Upper And Lower Control Limits That Indicate Whether Process Variation Is Within.

Web A Six Sigma Control Chart Is A Simple Yet Powerful Tool For Evaluating The Stability Of A Process Or Operation Over Time.

Edwards Deming, Spc Charts Offer Visual Representations Showcasing Workflow Shifts.

Related Post: