Pyrometric Cone Chart

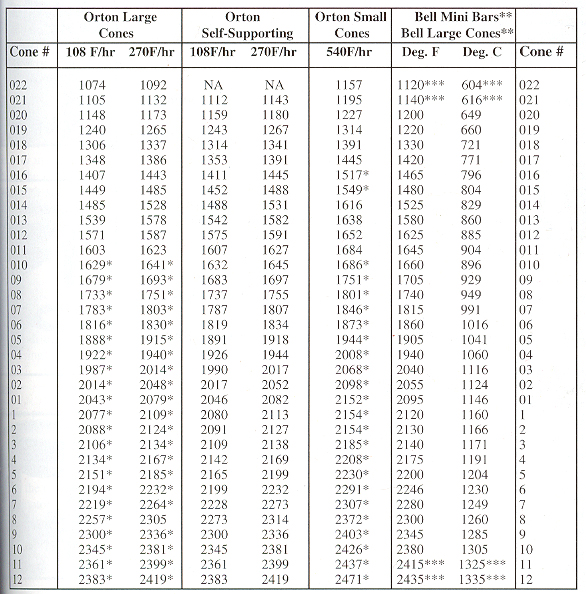

Pyrometric Cone Chart - Different heating rates will change the equivalent temperature. It is based on the use of pyrometric cones to measure heatwork in a kiln firing. Melted large orton pyrometric cones 5, 6 and 7. Web this comprehensive chart shows the temperatures of orton pyrometric cones in degrees f. Web pyrometric cones have been used to monitor ceramic firings for more than 100 years. Temperatures shown on the charts were determined under controlled firing conditions in electric kilns and an air atmosphere. (as determined at the national bureau of standards) large cones cone. Refer to this cone temperature chart before firing. Web pyrometric kiln cones measure heat absorption as kiln temperatures reach heating ranges. Cones are made from recipes of ceramic materials and minerals tuned to make them bend gradually through a target temperature range. Refer to this cone temperature chart before firing. Web utilize the orton cone temperature equivalents chart to select the correct cone numbers you will need. Web temperatures shown on the charts were determined under controlled firing conditions in electric kilns and an air atmosphere. They are useful in determining when a firing is complete, if the kiln provided enough heat, if there was a temperature difference in the kiln or if a problem occured during the firing. Web pyrometric cones have been used to monitor ceramic firings for more than 100 years. Web the orton cone chart was developed by edward orton, jr. Cone pack is pictured after being removed from the kiln. Web there are 4 styles of pyrometric cone: Web differences between a cone touching the shelf and a cone at the 4 o’clock position are small, usually 1 or 2 degrees. Web this pyrometric cone chart provides the temperature equivalents for orton cones based on specific heating rates. Web pyrometric cones are slender pyramids made from about 100 carefully controlled compositions. Each cone number is unique in measuring temperature within a small temperature range (less than 30°c). Web this comprehensive chart shows the temperatures of orton pyrometric cones in degrees f. Cone pack is pictured after being removed from the kiln. Web utilize the orton cone temperature equivalents. Different heating rates will change the equivalent temperature. Prior to their development there was no scientific means for indicating when to stop a kiln firing for optimal maturation of a clay body or glaze. Generally speaking, the temperatures in the 108°f/hour column are used when discussing ceramics, porcelain and china. Web pyrometric kiln cones measure heat absorption as kiln temperatures. Cones are made from recipes of ceramic materials and minerals tuned to make them bend gradually through a target temperature range. Web temperatures shown on the charts were determined under controlled firing conditions in electric kilns and an air atmosphere. Once the appropriate cones are selected, excellent, reproducible results can be expected. Keep the chart near your kiln for quick. These heating rates are for the last 100°c or 180°f of the firing. Pyrometric cones are pyrometric devices that are used to gauge heatwork during the firing of ceramic materials in a kiln. This guide provides useful information on cones and how firings can affect your pottery. Temperatures shown on the charts were determined under controlled firing conditions in electric. To produce a properly fired result, the next cone higher in sequence is placed into the shutoff device and the result is confirmed by a cone placed inside the kiln on a kiln shelf. Web orton pyrometric cone chart in fahrenheit and celsius. The cones, often used in sets of three, are positioned in a kiln with the wares to. Web download and print the orton cone wall chart at sheffield pottery. This guide provides useful information on cones and how firings can affect your pottery. Behavior of pyrometric cones pyrometric cones deform due to the formation of glass and the As discussed above, the equivalent cone temperature depends upon how fast one gets to it. Web orton pyrometric cone. Once the appropriate cones are selected, excellent, reproducible results can be expected. Temperatures shown on the charts were determined under controlled firing conditions in electric kilns and an air atmosphere. It is based on the use of pyrometric cones to measure heatwork in a kiln firing. Behavior of pyrometric cones pyrometric cones deform due to the formation of glass and. Cones are made from recipes of ceramic materials and minerals tuned to make them bend gradually through a target temperature range. Web these tables provide a guide for the selection of cones. Web pyrometric cones have been used to monitor ceramic firings for more than 100 years. Web this comprehensive chart shows the temperatures of orton pyrometric cones in degrees. Generally speaking, the temperatures in the 108°f/hour column are used when discussing ceramics, porcelain and china. These heating rates are for the last 100°c or 180°f of the firing. They are useful in determining when a firing is complete, if the kiln provided enough heat, if there was a temperature difference in the kiln or if a problem occured during. Once the appropriate cones are selected, excellent, reproducible results can be expected. Cones are made from recipes of ceramic materials and minerals tuned to make them bend gradually through a target temperature range. Cone pack is pictured after being removed from the kiln. They are useful in determining when a firing is complete, if the kiln provided enough heat, if. Web orton pyrometric cone chart in fahrenheit and celsius. This deforming action allows us to either shut the kiln off at the proper point (as in the case of the mini bar and kiln sitter) or simply to record what happened during the firing (as in the case of the witness cone). (as determined at the national bureau of standards) large cones cone. Refer to this cone temperature chart before firing. Web utilize the orton cone temperature equivalents chart to select the correct cone numbers you will need. Web all of our resources for orton's pyrometric cones. Web pyrometric cones are slender pyramids made from about 100 carefully controlled compositions. Temperatures are shown for specific heating rates. Web pyrometric cones are designed to deform at certain moments during a firing. Prior to their development there was no scientific means for indicating when to stop a kiln firing for optimal maturation of a clay body or glaze. Web this pyrometric cone chart provides the temperature equivalents for orton cones based on specific heating rates. The cones, often used in sets of three, are positioned in a kiln with the wares to be fired and, because the individual cones in a set soften and fall over at different temperatures, they provide. They are useful in determining when a firing is complete, if the kiln provided enough heat, if there was a temperature difference in the kiln or if a problem occured during the firing. Melted large orton pyrometric cones 5, 6 and 7. Behavior of pyrometric cones pyrometric cones deform due to the formation of glass and the These heating rates are for the last 100°c or 180°f of the firing.Potter's Pyrometric Cone Chart 18x24 POSTER Digital Printathome Tool

Potter's Pyrometric Cone Chart Digital PDF Printathome Etsy

Pyrometric Cone Chart xiymachine

Pyrometric Cone Chart xiymachine

Cone Firing Chart A Visual Reference of Charts Chart Master

Potter's Pyrometric Cone Chart Digital PDF Printathome Etsy

Pyrometric Cone Temperature Conversion Chart Pottery

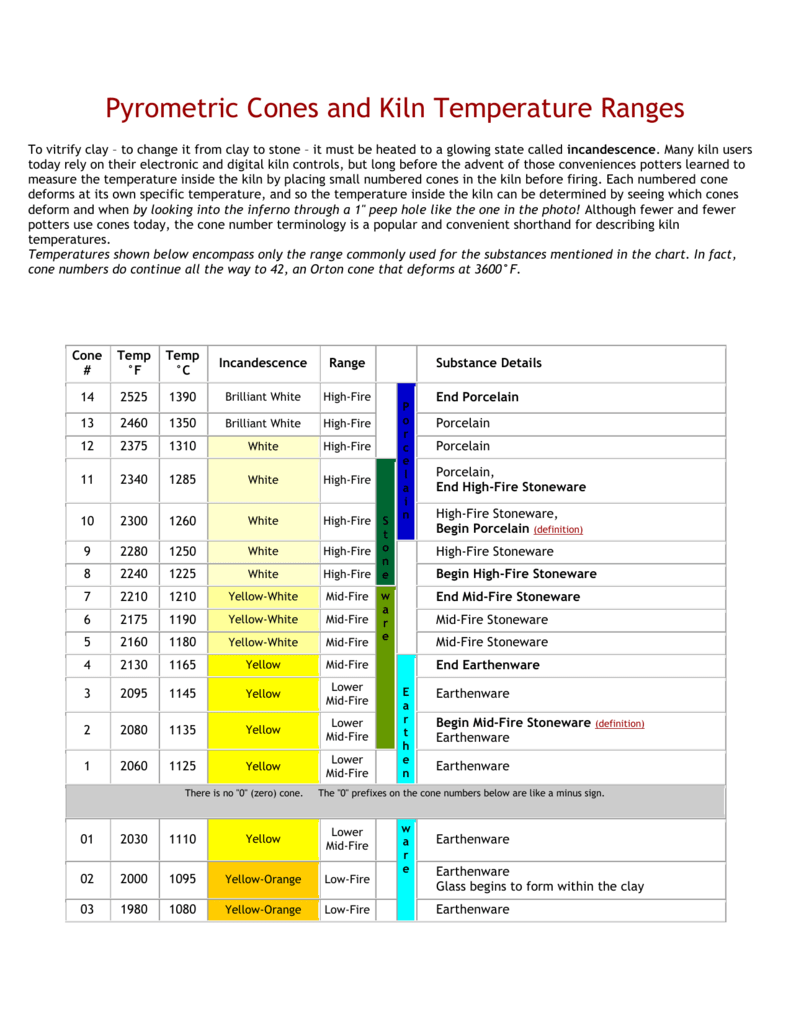

Pyrometric Cones and Kiln Temperature Ranges To vitrify clay to

Pyrometric Cone Chart for Kiln Firing

What is a Cone? A Guide to Pyrometric Cones and Kilns Soul Ceramics

Heating Rate In °C/Hr 60°C/Hr.

It Is Based On The Use Of Pyrometric Cones To Measure Heatwork In A Kiln Firing.

Each Cone Number Is Unique In Measuring Temperature Within A Small Temperature Range (Less Than 30°C).

Generally Speaking, The Temperatures In The 108°F/Hour Column Are Used When Discussing Ceramics, Porcelain And China.

Related Post: