Bearing Types Chart

Bearing Types Chart - It’s important to note that there are many variations and specialized designs within each bearing type to suit specific performance requirements and. There are many different types of bearings, each with its own unique set of benefits and applications. Choose an angular contact bearing. Shaft and housing fits for electric motor bearings. This guide will dive into different types of bearings and their uses, along with the definition, function, and classification of bearings. Radial bearings radial bearings are types of bearings that primarily used for supporting radial loads, although under some circumstances they are capable of carrying limited thrust loads. Axial (thrust) (parallel to the shaft) loads: The direction of load is a primary factor in bearing type selection. The main factors to be considered when selecting the correct type are: Understanding these distinctions is crucial for selecting the right bearing for specific machinery and equipment needs, ensuring optimal performance and durability. Precision levels and allowable deviations in dimensions. Detailed measurements including id, od, and width. Explore our wide assortment of rolling bearings, accessories and services that best meet your specific performance needs. Both dynamic and static load ratings indicating the maximum load capacity. Matrix 1 gives an overview of the main bearing types (including their major features and design variants) and their degree of suitability for certain aspects of use. The manufacturing process for deep groove ball bearings is shown below. The complete bearing designation may consist of a basic designation with or without one or more supplementary prefixes and suffixes ( diagram 1 ). This article decodes bearing designations, revealing how their types, sizes, and structures are identified. Combined radial and axial loads. Choose an angular contact bearing. Web a bearing is a support device that allows for relative motion between two or more parts. Web this chart provides a basic overview of some common bearing types, their features, and typical applications. This article decodes bearing designations, revealing how their types, sizes, and structures are identified. Web have you ever wondered how engineers ensure the smooth operation of. The main factors to be considered when selecting the correct type are: Web matrix 1 provides an overview of the suitability of various bearing types for different bearing arrangements. Web there are many types of bearings, and manufacturing processes with many fine points of difference according to the type of bearing. There are many different types of bearings, each with. They are downloadable and printable so you can get the details you need to choose the right bearing. Combined radial and axial loads. An example of dynamic misalignment would be a vibrating screen with rotating imbalance and therefore rotating deflection of the shaft. Understanding these distinctions is crucial for selecting the right bearing for specific machinery and equipment needs, ensuring. Web before determining the best bearing for your application, it is necessary to identify the bearing type and characteristics. Identifies the type of bearing (e.g., deep groove ball bearing, spherical roller bearing). The supporting device is known as a bearing. Radial bearings are some of the most common types of bearings on the market. A single bearing arrangement consists of. Web from this point of view, bearings are grouped into three main categories: Web matrix 1 provides an overview of the radial, axial and moment load capability of various bearing types. By the end, you’ll understand the essential codes that keep machines running efficiently. Matrix 1 gives an overview of the main bearing types (including their major features and design. The main factors to be considered when selecting the correct type are: Web matrix 1 provides an overview of the radial, axial and moment load capability of various bearing types. They are downloadable and printable so you can get the details you need to choose the right bearing. Bearings typically allow for low friction movement and can be found in. Choose radial ball bearings (also known as deep groove ball bearings). Classification and characteristics of rolling bearings. Explore our wide assortment of rolling bearings, accessories and services that best meet your specific performance needs. Generally speaking, bearing manufacturing consists of the processes of forging, turning, heat treatment, grinding, and assembly. Radial bearings are some of the most common types of. This article will delve into the features, differences, and appropriate applications of 14 common types of bearings. Web there are many types of bearings, and manufacturing processes with many fine points of difference according to the type of bearing. Web radial (perpendicular to the shaft) and light loads: The supporting device is known as a bearing. Axial (thrust) (parallel to. They facilitate smooth operations in. A single bearing arrangement consists of just one bearing that supports radial, axial and moment loads. Web these help narrow down the bearing selecting process. Web the bearing size chart helps identify the dimensions and specifications of bearings, making it a crucial tool for selection. Web the most common bearing application is the ball bearing. Axial (thrust) (parallel to the shaft) loads: Combined radial and axial loads. Web matrix 1 provides an overview of the radial, axial and moment load capability of various bearing types. A single bearing arrangement consists of just one bearing that supports radial, axial and moment loads. This article will delve into the features, differences, and appropriate applications of 14 common. Axial (thrust) (parallel to the shaft) loads: By the end, you’ll understand the essential codes that keep machines running efficiently. Web the designations of most skf rolling bearings follow a designation system. Generally, all types of machinery are provided with supports for rotating shafts. Choose radial ball bearings (also known as deep groove ball bearings). Web radial (perpendicular to the shaft) and light loads: Web a bearing is a support device that allows for relative motion between two or more parts. These bearings are often chosen for applications with high dynamic misalignment. They facilitate smooth operations in. Choose an angular contact bearing. Web matrix 1 provides an overview of the radial, axial and moment load capability of various bearing types. Web before determining the best bearing for your application, it is necessary to identify the bearing type and characteristics. This movement is either rotary (shaft rotating within a mount) or linear (one surface moving along another). Web each type of bearing has characteristic properties which make it particularly suitable for certain applications. Radial bearings, thrust bearings, and linear bearings. Web focus on 14 common types of bearings.15 Types of Bearings and Their Applications [Pictures & PDF]

Bearing Types PDF Bearing (Mechanical) Machines

Guide to the Different Ball Bearing Types Electrical Apparatus

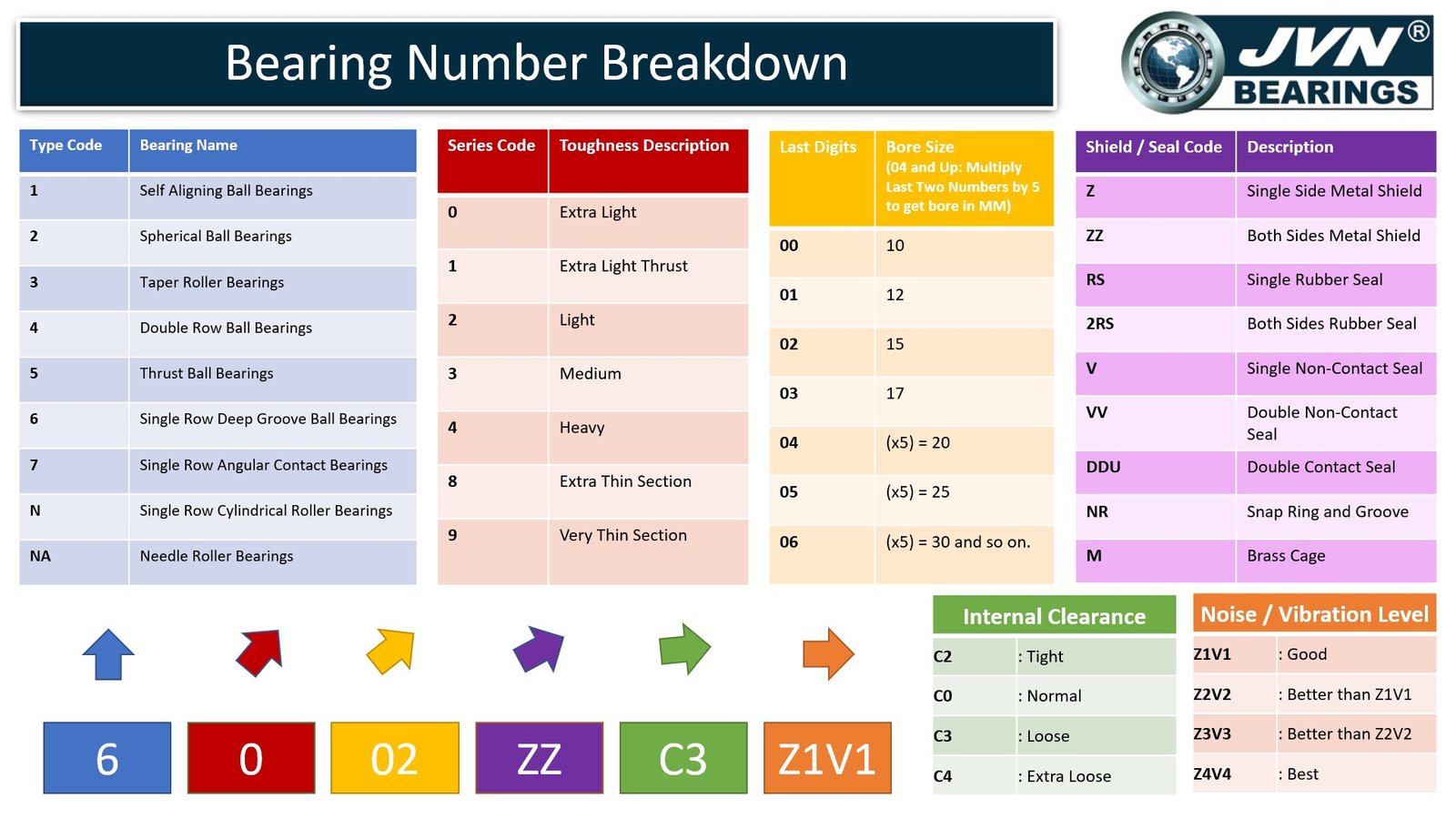

Bearing Numbers Meaning JVN Bearings FZE Manufacturer, Supplier

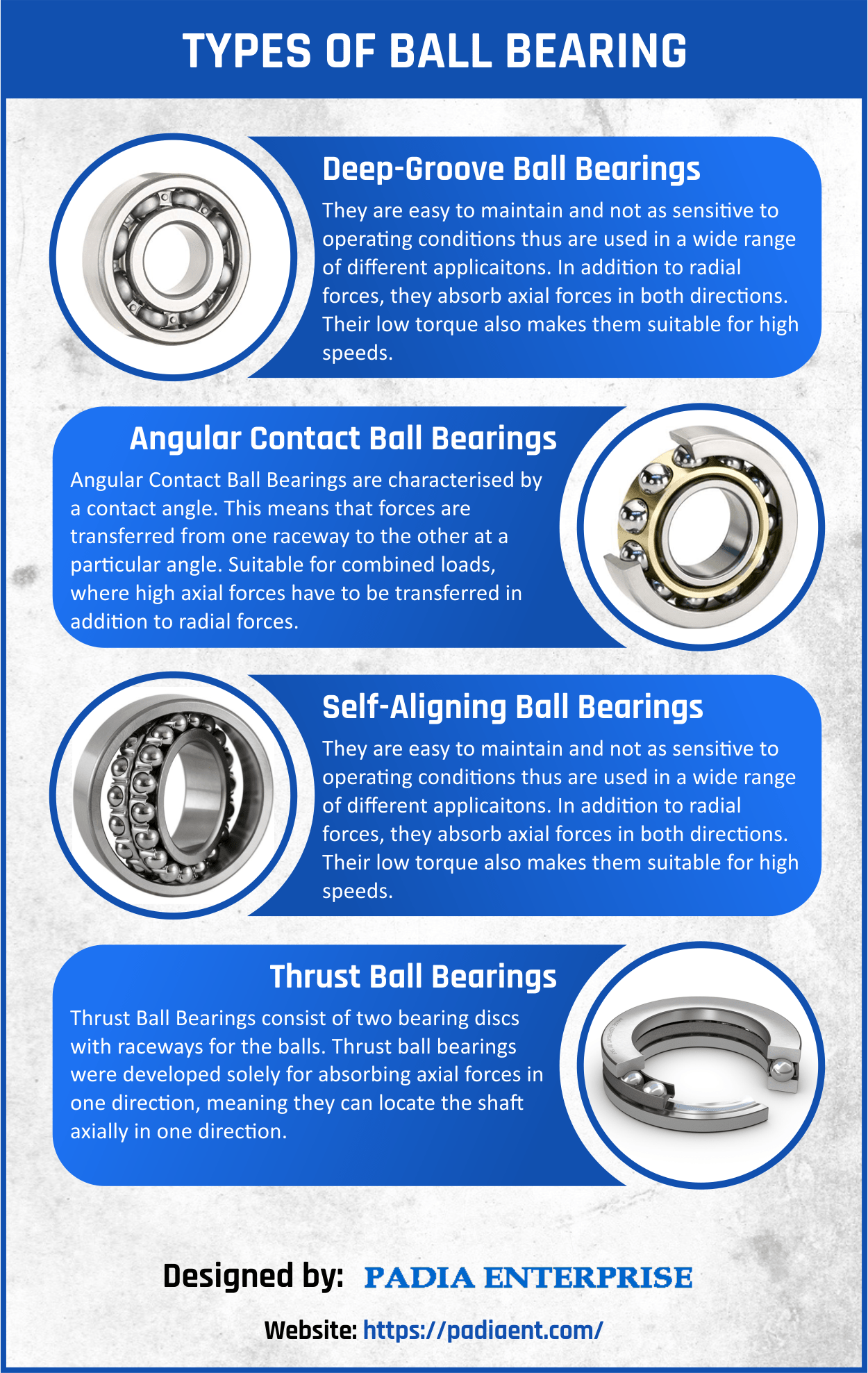

Types of Ball Bearing Infographic

Bearing Type Chart.pdf

Types Of Ball Bearing Infographic vrogue.co

Types of Bearings Definition, Function, Uses, Advantages

What Is Bearing? Types Of Bearings And Classification. Metal working

Types of Bearings Definition, Function, Uses, Advantages

Combined Radial And Axial Loads.

Web There Are Many Types Of Bearings, And Manufacturing Processes With Many Fine Points Of Difference According To The Type Of Bearing.

It’s Important To Note That There Are Many Variations And Specialized Designs Within Each Bearing Type To Suit Specific Performance Requirements And.

In Other Words, A Bearing Is A Machine Element That Constrains Relative Motions And Is Used To Reduce The Friction Between Moving Parts.

Related Post:

![15 Types of Bearings and Their Applications [Pictures & PDF]](https://www.theengineerspost.com/wp-content/uploads/2018/09/Types-of-Bearings.jpg)