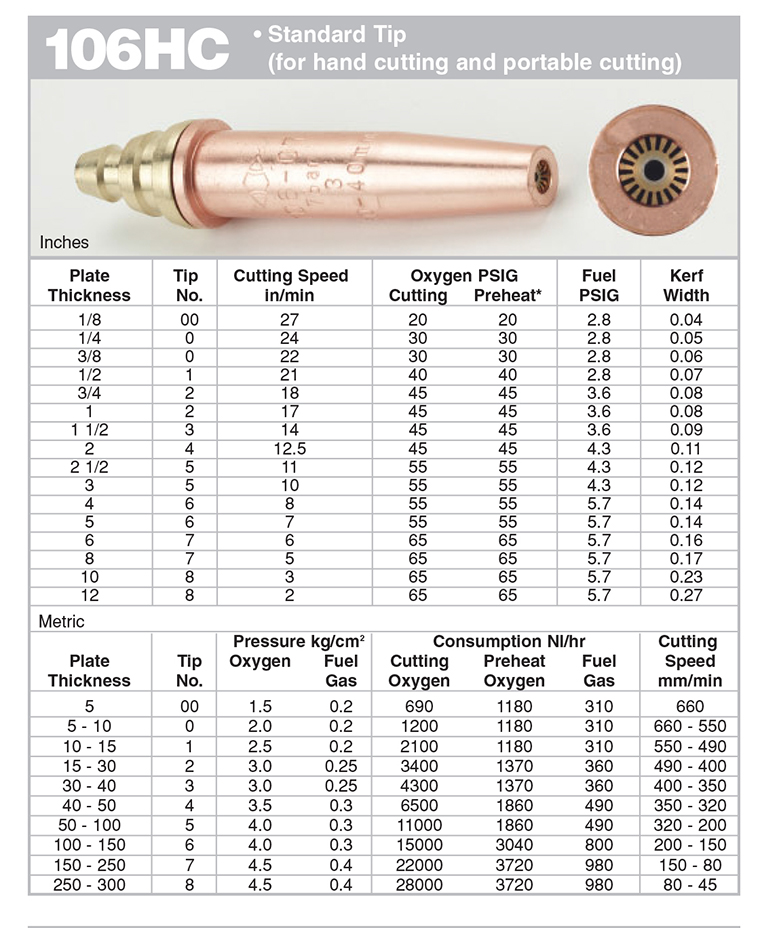

Acetylene Torch Settings Chart

Acetylene Torch Settings Chart - Numbers are for your convenience only. How to set up an oxy acetylene cutting torch pressure. It combines oxygen and acetylene gases to form a superheated flame that melts and joins two pieces of metal. And i usually guess at the others so i figured i'd ask the experts what typical settings would be for all of 'em and write 'em down for future reference. Web do you have an oxygen acetylene torch? It's been so long since i've used our rosebud tip i've forgotten what oxygen and acetylene pressure settings to use. Here are 4 simple steps to selecting the correct one for your project to ensure clean cuts. This guide provides all the information you need, from choosing the right equipment to tips for safe and efficient operation. It is an intricate process that requires a great degree of skill, focus and patience, but don’t be discouraged. Web the ideal cutting settings for oxy acetylene depend on factors like material type, thickness, and torch tip size. Make use of correct welding & cutting technique. Open the oxygen valve present on the welding torch. How to set up an oxy acetylene cutting torch pressure. In addition to these easy to follow instructions, you must always be sure to follow the torch manufacturer’s operating procedures. It's been so long since i've used our rosebud tip i've forgotten what oxygen and acetylene pressure settings to use. · make sure torch valves are closed! Web january 25, 2023 | 12:38 pm. It combines oxygen and acetylene gases to form a superheated flame that melts and joins two pieces of metal. It can be used for welding, cutting, and soldering a variety of metals, including steel, brass, and copper. · stand away from front of regulator · separately and slowly. Adjust to the correct flame setting. It can be used for welding, cutting, and soldering a variety of metals, including steel, brass, and copper. It is an intricate process that requires a great degree of skill, focus and patience, but don’t be discouraged. Open the oxygen valve present on the welding torch. You'll also need to connect the gas supplies,. How to set up and use. This guide provides all the information you need, from choosing the right equipment to tips for safe and efficient operation. You'll also need to connect the gas supplies, like the oxygen and the acetylene hoses, to the torch. Numbers are for your convenience only. Web do you have an oxygen acetylene torch? Web the ideal cutting settings for oxy acetylene depend on factors like material type, thickness, and torch tip size. Most parts advertised for sale are made. Open regulator oxygen and acetylene, set until the pressure matches with what you want or for acetylene 5 to 7 psi and oxygen 7 to 10 psi. What is the maximum working pressure for. Numbers are for your convenience only. Web setting the correct working pressures. Open the oxygen valve present on the welding torch. Web do you have an oxygen acetylene torch? Discover welding techniques, tips, and more. This guide provides all the information you need, from choosing the right equipment to tips for safe and efficient operation. Web the ideal cutting settings for oxy acetylene depend on factors like material type, thickness, and torch tip size. Adjust to the correct flame setting. First, we must clean the nozzle because if the head of the nozzle is dirty. · stand away from front of regulator · separately and slowly. This guide provides all the information you need, from choosing the right equipment to tips for safe and efficient operation. Make use of correct welding & cutting technique. How to set up and use. Web mastering the oxy acetylene cutting torch settings is essential for achieving clean and efficient. And i usually guess at the others so i figured i'd ask the experts what typical settings would be for all of 'em and write 'em down for future reference. Web setting the correct working pressures. It is an intricate process that requires a great degree of skill, focus and patience, but don’t be discouraged. Numbers are for your convenience. How to set up an oxy acetylene cutting torch pressure. Web do you have an oxygen acetylene torch? By understanding the basics, selecting the right tip, setting proper gas pressures, and following the correct cutting techniques, you. Web mastering the oxy acetylene cutting torch settings is essential for achieving clean and efficient cuts. Web january 25, 2023 | 12:38 pm. Whether it's your first time using your gas cutting torch or a pro, use this guide to ensure a safe set up. Open the oxygen valve present on the welding torch. Pure oxygen is used for the cutting jet and it's mixed with either acetylene, propane, or commercial gas to provide the preheat flames. In today's video, western welding academy's,. What is the ratio between the two gases? How to light oxy acetylene torch. Web to set up an oxy acetylene torch, start by cleaning any dust or dirt from the valve outlet. · stand away from front of regulator · separately and slowly. · make sure regulator pressure adjustment screws are backed out! Web this article covers the standard type of cutting torch which is an acetylene torch set up. It combines oxygen and acetylene gases to form a superheated flame that melts and joins two pieces of metal. This guide provides all the information you need, from choosing the right equipment to tips for safe and efficient operation. How to set up and use. Make use of correct welding & cutting technique. Web oxy acetylene welding set up and pressure settings chart : Pure oxygen is used for the cutting jet and it's mixed with either acetylene, propane, or commercial gas to provide the preheat flames. Open the oxygen valve present on the welding torch. How to light oxy acetylene torch. It is an intricate process that requires a great degree of skill, focus and patience, but don’t be discouraged. Adjust to the correct flame setting. The recommended setting is for the fuel gas regulator to be set at 10 psig and the oxygen regulator at 45 psig. What is the ratio between the two gases? Discover welding techniques, tips, and more. Web setting the correct working pressures. Web the ideal cutting settings for oxy acetylene depend on factors like material type, thickness, and torch tip size.4 Best Images of Victor Acetylene Cutting Tip Chart Victor Acetylene

Oxyacetylene Torch Settings Chart

Oxy Acetylene Cutting Torch Settings Chart A Visual Reference of

Oxy Acetylene Torch Tip Chart

Oxy Acetylene Torch Tip Chart

Oxy Acetylene Torch Tip Chart

Cutting Torch Guide

Oxyacetylene Torch Settings Chart

Oxyacetylene Torch Settings Chart

Oxyacetylene Torch Settings Chart

It's Been So Long Since I've Used Our Rosebud Tip I've Forgotten What Oxygen And Acetylene Pressure Settings To Use.

Most Parts Advertised For Sale Are Made.

Here Are 4 Simple Steps To Selecting The Correct One For Your Project To Ensure Clean Cuts.

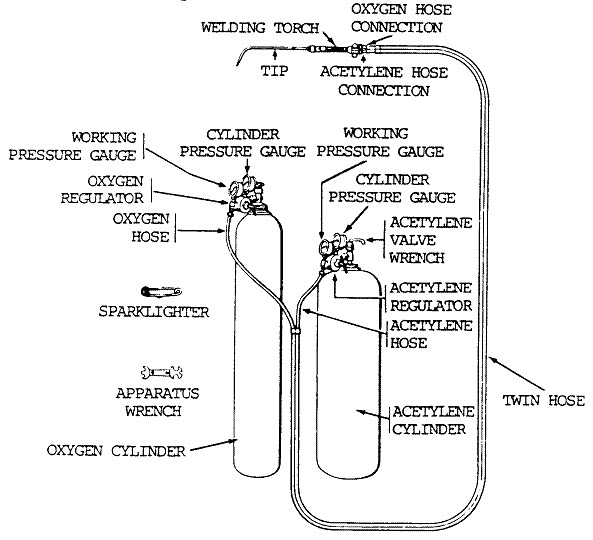

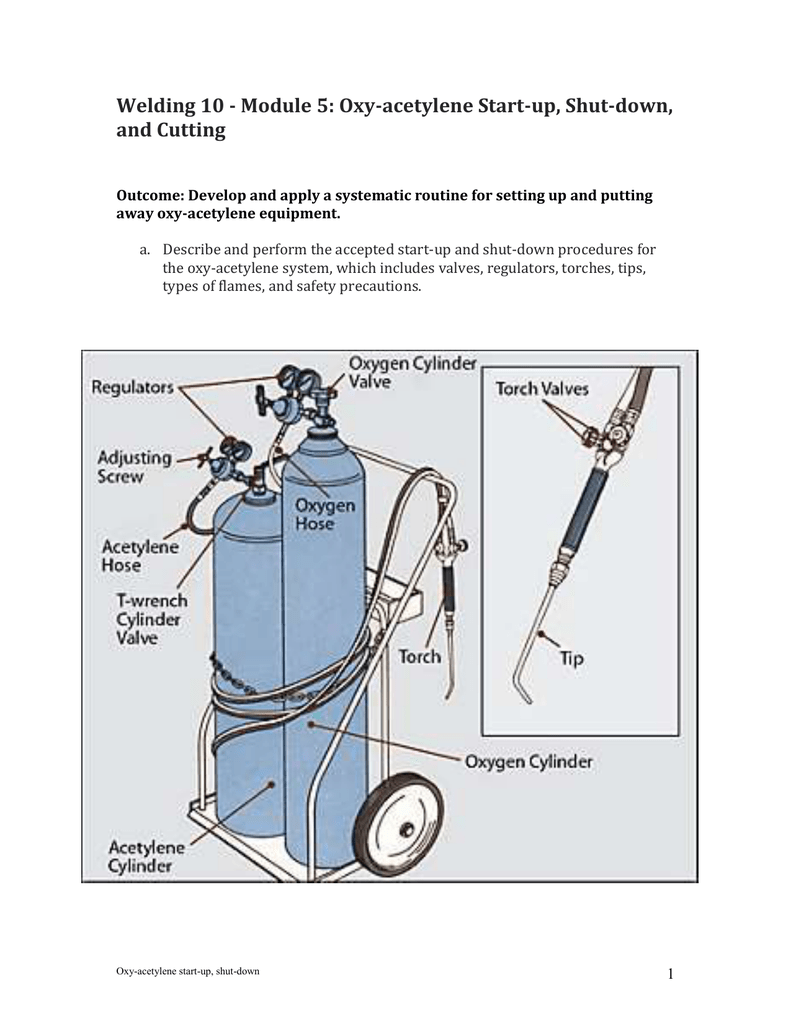

How To Set Up An Oxy Acetylene Cutting Torch Pressure.

Related Post: