7018 18 Welding Rod Amperage Chart

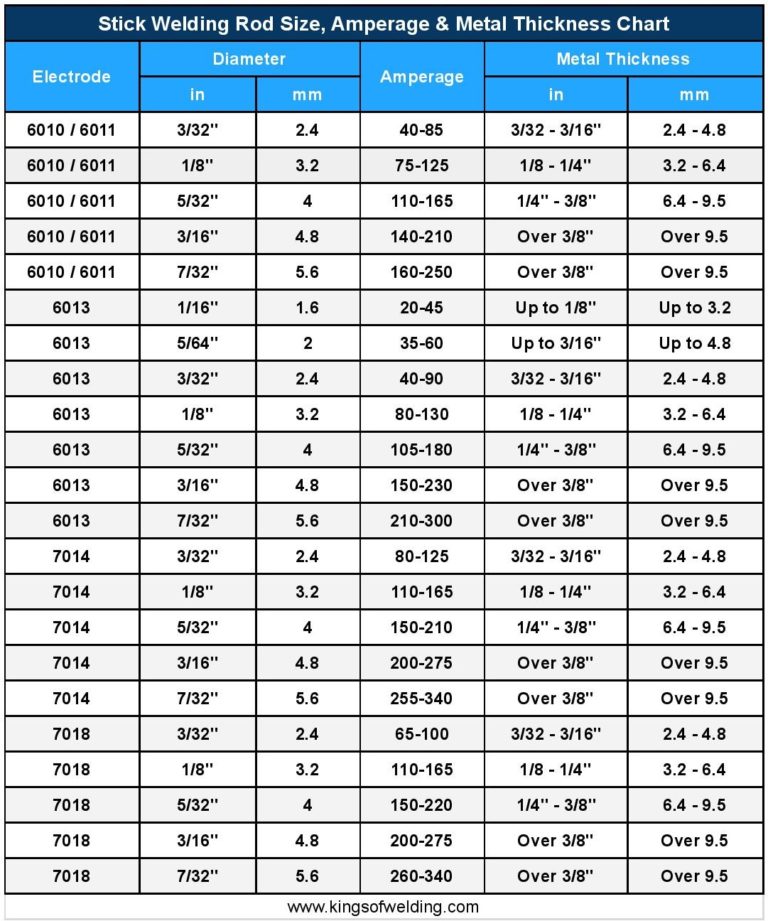

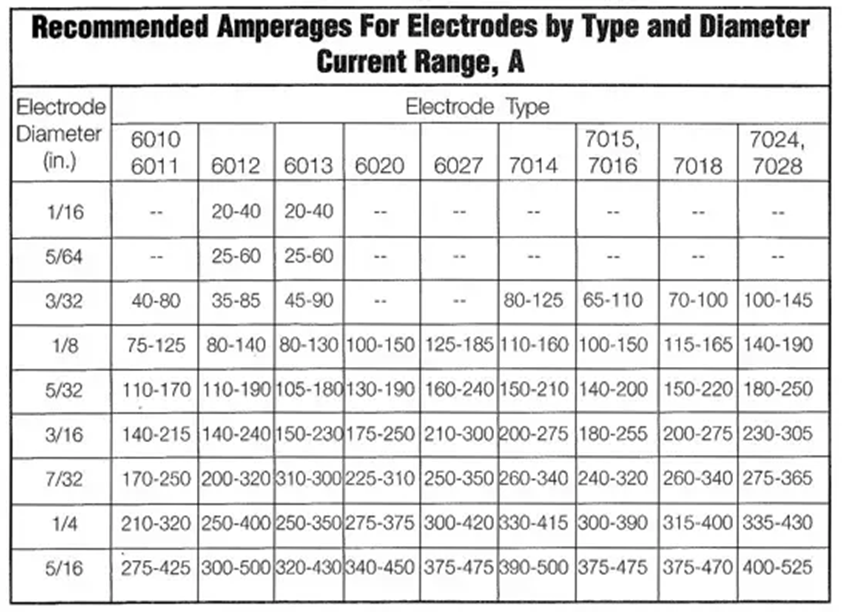

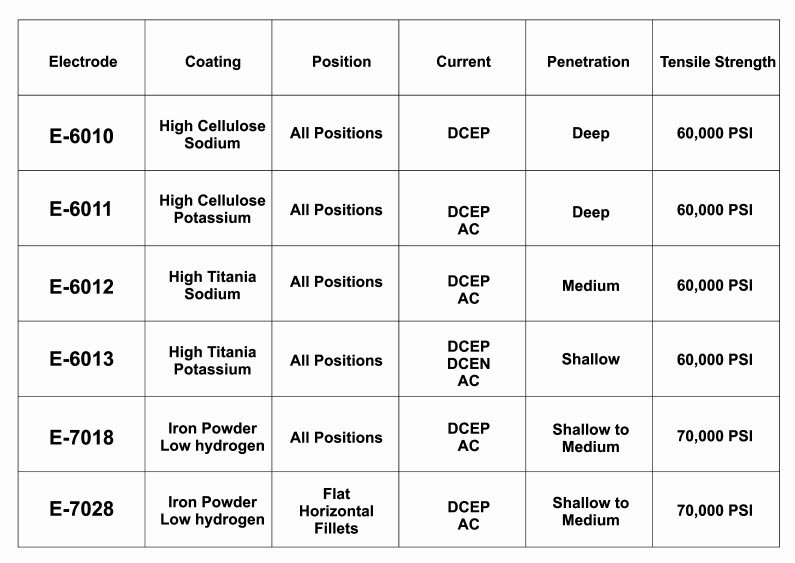

7018 18 Welding Rod Amperage Chart - Yes i have adjusted holding welding rod angle for more or less penetration. E7018m has higher weld deposit toughness than e7018 rod. Web according to this chart, a 3/32 inch rod requires at least 65 amps for flat welding and vertical welding. The e7018 has a tensile strength of 70,000psi and can be used in almost all positions. Strong welds on clean metal. Web let’s take e7018, for example. Web what material are you welding? Web e7018m welding electrode amperage chart. Web what size is a 7018 welding rod? For example, a 1/8″ 6011 rod would be 100a at its middle amperage. Commonly used in structural welding. It produces fluid, thick slag, uniform beads and has medium penetration. Web what size is a 7018 welding rod? 7018 welding rod sizes are 3/32, 1/8, 5/32 and 3/16 inches. Web there is a recommended amperage for every corresponding rod diameter size or for the thickness of steel you plan to weld with the 7018 rods. Web what material are you welding? For example, a 1/8″ 6011 rod would be 100a at its middle amperage. Welding around this amperage should give good fusion, no sticking and not too much heat. Web according to this chart, a 3/32 inch rod requires at least 65 amps for flat welding and vertical welding. E7018m has higher weld deposit toughness than e7018 rod. Web setting the amperage on a welding machine, whether stick (smaw), mig (gmaw) (*typically uses voltage setting), or tig (gtaw), depends on some key variables such as application and base material, welding process, and electrode. E stands for the electrode. With these settings, there is a high chance that you will be able to achieve a decent weld. Web there. Web i have compiled a full guide about everything there is to know about the 7018 electrodes, and i hope it helps you out. E7018m vs e7018 welding rod. How to choose welding rod amperage. Yes i have adjusted holding welding rod angle for more or less penetration. Web there is a recommended amperage for every corresponding rod diameter size. Web may 23, 2023. The 7018 welding rod is primarily used for carbon steel (low, medium, and high) and low alloy steel of higher strength. A higher psi means a stronger electrode when welded. Electrode amperage chart.pdf created date: The cost of e7018m is higher than e7018. Commonly used in structural welding. Web may 23, 2023. Web setting the amperage on a welding machine, whether stick (smaw), mig (gmaw) (*typically uses voltage setting), or tig (gtaw), depends on some key variables such as application and base material, welding process, and electrode. Web e7018 size and amperage chart. Web i have compiled a full guide about everything there. Web according to this chart, a 3/32 inch rod requires at least 65 amps for flat welding and vertical welding. How to choose welding rod amperage. 7018 has a very good deposition rate, providing a quiet, steady arc with low spatter and medium penetration. You can refer to the rod manufacturer’s manuals for setting up the accurate amps. Web e7018. It produces fluid, thick slag, uniform beads and has medium penetration. Web because it's one of the most popular materials for stick welding, it's important to know the basics about this material, such as 7018 welding rod amperage. Once you determine these three main variables, you can set your welding machine and start laying a weld bead. 7018 has a. Browse suggested weld parameter settings for stick welding. Web if you aren’t sure which type of electrode to buy then look at our comparison of 6010 vs 6011 vs 6013 vs 7018 vs 7024. E7018m vs e7018 welding rod. It has many benefits, including good arc control, easy ignition, and more. Web e7018 welding rod amperage & current. 7018 welding rod sizes are 3/32, 1/8, 5/32 and 3/16 inches. 7018 has a very good deposition rate, providing a quiet, steady arc with low spatter and medium penetration. Web there is a recommended amperage for every corresponding rod diameter size or for the thickness of steel you plan to weld with the 7018 rods. Web e7018m welding electrode amperage. E7018 is dcep/ac rod, with low hydrogen potassium and iron powder composition. Welding around this amperage should give good fusion, no sticking and not too much heat. It has many benefits, including good arc control, easy ignition, and more. Web e7018m welding electrode amperage chart. Web what size is a 7018 welding rod? Here’s how to break down this number, according to the american welding society: Web a good starting point for setting your amperage is to choose an amperage in the exact middle of the range for a horizontal fillet weld. Once you determine these three main variables, you can set your welding machine and start laying a weld bead. Web e7018. High deposition, only suitable for flat and horizontal welds. Web a good starting point for setting your amperage is to choose an amperage in the exact middle of the range for a horizontal fillet weld. Web e7018m welding electrode amperage chart. Yes i have adjusted holding welding rod angle for more or less penetration. Web there is a recommended amperage for every corresponding rod diameter size or for the thickness of steel you plan to weld with the 7018 rods. The 7018 welding rod is primarily used for carbon steel (low, medium, and high) and low alloy steel of higher strength. A higher psi means a stronger electrode when welded. Plus you'll get the most complete welding rod chart on the internet in pdf! Strong welds on clean metal. Web our powerful calculator let's you easily determine which stick electrode you need. Electrode amperage chart.pdf created date: If you are looking for a reliable and strong welding rod to help complete your next big project, 7018 welding rods are perfect. Web e7018 welding rod amperage & current. Welding around this amperage should give good fusion, no sticking and not too much heat. E7018m vs e7018 welding rod. E stands for the electrode.7018 Welding Rod Amperage Chart

Welding Rod Amperage Chart

Welding Rod Sizes, Amperage & Metal Thickness Chart Kings of Welding

7018 1/8 Welding Rod Amperage Chart

Welding

Welding Rod Amperage Chart Pdf

Welding Rod Amperage Chart

ضبط الامبير للحام القواعد الذهبية فى اللحام القاعدة الرابعةWelding

Welding Rod Amperage Chart Pdf

Metal Thickness Stick Welding Amperage Chart

The First Two Digits Refer To The Tensile Strength, Measured In Psi (Pounds Per Square Inch).

E7018M Can Only Be Used With Dcep Polarity When E7018 Can Be Used With Ac And Dcep.

Due To Fluid Slag, It Can Be Run In All Positions Except Vertical Down.

It Also Needs The Same Minimal Amps For Overhead Welding.

Related Post: